It’s unlikely that you’ve given much thought to the many varieties and qualities of paper unless you’re an artist or a printmaker.

Even while terms like “bond paper” and “bleedproof paper” aren’t commonly used, knowing what they mean might help you find the perfect paper for your project.

Bleedproof refers to a feature of the paper, not to a specific type of paper. When a piece of paper is labeled “bleedproof,” it signifies that an invisible coating has been applied to prevent ink from seeping through the paper and onto the opposite side.

Table of Contents

Types of paper that are bleedproof

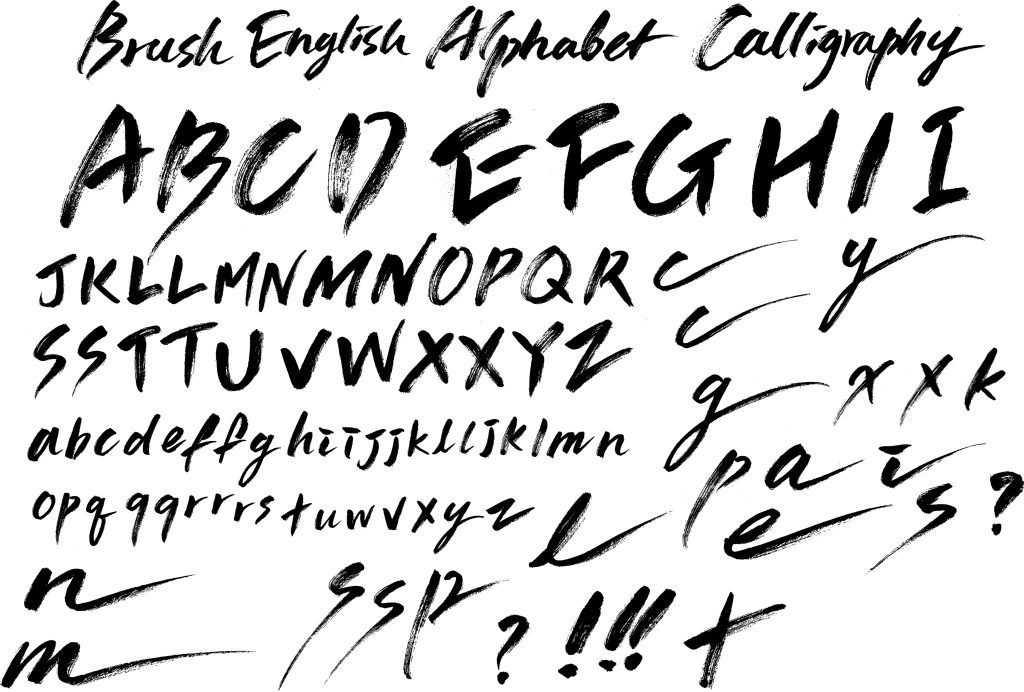

Some papers, such as calligraphy, marker, and Bristol paper, you would describe as being bleedproof.

Bleedproof paper is available in a wide range of paper sizes, usually in the form of pads rather than reams, because of its vast range of applications.

Sketchbooks with bleedproof paper are also available.

Bleedproof paper is desirable for artists who deal with wet mediums, such as water-based or spirit-based felt pens.

Smears, feathering, and other problems on the paper’s underside are common when ink is used on non-bleedproof media, including bonds, construction paper, and card stock.

It’s tough to blend colors on regular paper and wasteful since it absorbs ink too rapidly. These problems can be avoided by using bleedproof paper.

What are the options for bleedproof paper?

There is no need to hunt for bleedproof paper for everyday printing and copying. Instead of bleedproof paper, consider using bond paper, which is specifically made for these uses, readily available in reams, and generally less expensive.

A sheet of bond paper might suffice if you only needed some inexpensive paper for taking notes or making pencil sketches, rather than relying on expensive bleedproof paper.

Can you write on bleedproof paper?

Even while practicing with ink, bleedproof paper is the finest option. Handwriting and calligraphy can also be done on bleed-proof paper.

Using improper paper and receiving bad results can be upsetting for novices, who might profit from bleedproof paper’s characteristics as they master their techniques.

But if you’re planning to sell or display your artwork, you may want to look for more expensive bleedproof paper.

The paper-making process

When fibers are combined and rolled into sheets, paper is created. While paper created from chemically processed wood pulp is the least expensive, it is also the least durable and fades more quickly than paper made from cotton or linen.

Hot-pressed wood pulp and woven-fiber paper produce a gleaming finish.

Ink and pencil work well on different weights of hot-press paper. Drawings made with charcoal or chalk will not be able to adhere to this surface.

The heavier the weight, the more resilient it is to repeated erasures and the more forgiving it is.

Making coarse paper

Using a cold press, one can produce coarse paper. Chalk and charcoal stick better to the grainier surface.

Watercolors look their best on heavier, coarser paper because it is less likely to curl or buckle when washed.

It is a type of drawing paper that holds graphite medium very well. Ingres’s paper is coarse.

Many of Vincent Van Gogh’s watercolors were painted on Ingres’s paper.

Known as Arches, this 140-pound-weight paper is coarse on one side but smooth on the other, making it ideal for artists working in a wide range of media and techniques.

What did artists use before bleedproof paper?

Goatskin and sheepskin were employed by early artists for their drawings. Tracing, calligraphy, and drafting were all done on vellum drawing paper made from these translucent parchments.

Wood and cotton can both be used to make vellum. The fibers are boiled and rolled into thin layers before being processed.

Vellum in bright or pastel colors is available for artists who want to add a dash of color to their work.

The differences between bleedproof and bleedthrough papers

Marker paper that is labeled “bleedproof” means that markers will not bleed through it, but it does indicate that they will not feather when used with markers.

Most papers will bleed through alcohol-based markers, especially the thinner 70 to 80gsm marker sheets.

Alcohol markers, by their very nature, saturate the paper.

A lot of individuals have complained about the bleedthrough of bleedproof paper in marker paper evaluations.

However, the confusion is rational, but it is frustrating when trying to determine whether or not a marker paper is decent.

On a paper labeled “bleedproof,” ink should not bleed to the edges, but it can still be absorbed by the paper’s fibers.

If you want to draw on both sides of a piece of paper using alcohol-based markers, you need marker paper that is “resistant to bleed.”

It starts at 220gsm, which is the thinnest paper you’ll come across in this grade. “Bleedproof” and “resistant to bleedthrough” are two completely different terms that mean very different things.

Both copics won’t feather and copics won’t pierce through the paper when used on the former.

Layout paper vs marker papers

Even though they appear to be very similar and are frequently grouped, and even though they appear to be the same product, they are very different.

An explanation of the differences between both types of paper includes a lot of shared characteristics.

There is no denying that these papers are substantially similar. Paper’s weight and texture are two of the most crucial factors to consider when purchasing it, and on the surface, both marker and layout paper appear identical.

Lightweight (sub 100gsm) and incredibly smooth surfaces make them ideal.

Weight

Layout paper, on the other hand, is somewhat heavier than tracing paper at roughly 45gsm, making it quite similar in weight (and something you can use layout paper for).

Marker paper weighs about 70 gsm, which makes it thicker but also less transparent, making it less suitable for tasks like tracing.

Production

When it comes to creating a smooth paper surface, most of the paper-making processes will be similar.

However, the wax treatment added to the back of the marker paper sheet makes a significant distinction between the two.

Every marker sheet needs this process to ensure that the paper does not bleed. If you’re doing cartoon drawings, you’ll need a paper that won’t bleed through to the next sheet or run the ink.

Winsor and Newton Marker’s paper is a good option for this.

Uses

In terms of functionality, Marker papers should be used for alcohol markers, whereas layout papers should be used for brainstorming and designing the final product’s layout and design.

A technical pencil and brilliant and colorful ink can be utilized with each.

Economical

There isn’t much of a comparison here, but we think it’s a good way to show how inexpensive they are.

A high-quality layout or marker pad can be significantly less expensive than a high-quality cartridge pad, with both containing roughly 50 sheets on average.

Most Common Types of Paper

Many different varieties of paper are available to meet the needs of various applications or industries.

Composition, manufacture, and handling characteristics vary from type to kind. Before deciding on a material for a project, it’s critical to familiarize yourself with each of these categories.

This article presents an overview of the most popular papers on the market to help you make an informed decision.

Printing/Offset Paper (Repro)

Often referred to as offset or printing paper, this ubiquitous paper is produced in vast quantities and is widely available.

Printing is the primary use for these sheets, which are typically manufactured with a small portion of cellulose and a large amount of filler.

Weights range from 70 to 90 grams but can go up to 100 grams if necessary.

Newsprint

The name “newsprint” comes from the fact that it is a type of paper used in the printing of newspapers.

For obvious reasons, it has a short lifespan. Because the paper does not have to be white, high-quality materials are not required, and mechanical pulp, including residue, is used in the manufacturing process.

It is rarely colored, but when it is, a mass-dying process is used to apply the color.

Coated or Couche Paper

The filler is attached to the fiber by a binding agent, which can be synthetic or natural, in the production of coated paper, which has a higher proportion of short than long fibers (normally calcium carbonate).

To improve printing quality and resolution, cellulose is coated (on account of the higher screens).

This is due to the ink remaining on the surface, which results in a more lustrous and vibrant print after printing.

Tissue Paper

This fabric has a good absorption rate and a pleasant hand. To prevent them from coming apart when used, handkerchief and napkin paper need to be water-resistant, while napkin paper needs to be water-dissolvable when used.

To achieve this, several treatments are used during the production process, and they are often made from virgin fiber.

Fine Arts Paper

Depending on the artistic method, fine arts paper must have distinct technical and practical features.

These papers were developed as a less-expensive alternative to canvas.

In actuality, a few of these papers have superior characteristics and therefore can resist almost a hundred years of use before discoloring.

Cardboard

It’s not always obvious that cardboard is made of paper because of its thickness. Because it’s created from natural, unbleached wood pulp, it retains its natural, dark brown hue.

Recycled materials are commonly used because appearance does not play a role. Corrugated inner layers give cardboard its characteristic strength.

Cardboard is made up of three layers of paper: two smooth outer layers and one corrugated inner layer.

Paperboard

Numerous food containers, including cereal or cookie wrapping, are made of this polymer.

Paperboards are produced of short, non-virgin fibers because the inner part doesn’t have to be white, and therefore the fibers are not virgin.

Coated surfaces are common, and they serve as both a printing surface and a means of guaranteeing the exterior and apparent side appearance, which in turn helps to draw attention to the product.